The Leka warm roof conservatory system has been engineered through innovation, technical design and years of practical experience to create probably the best conservatory roof system available.

With thousands of happy homeowners enjoying the benefits of their Leka roof, this is a proven roofing system that is widely recommended in the trade. It can replace the roof on most existing conservatory builds including most glass, fibreglass and polycarbonate roofing systems, all without the need for additional bracing.

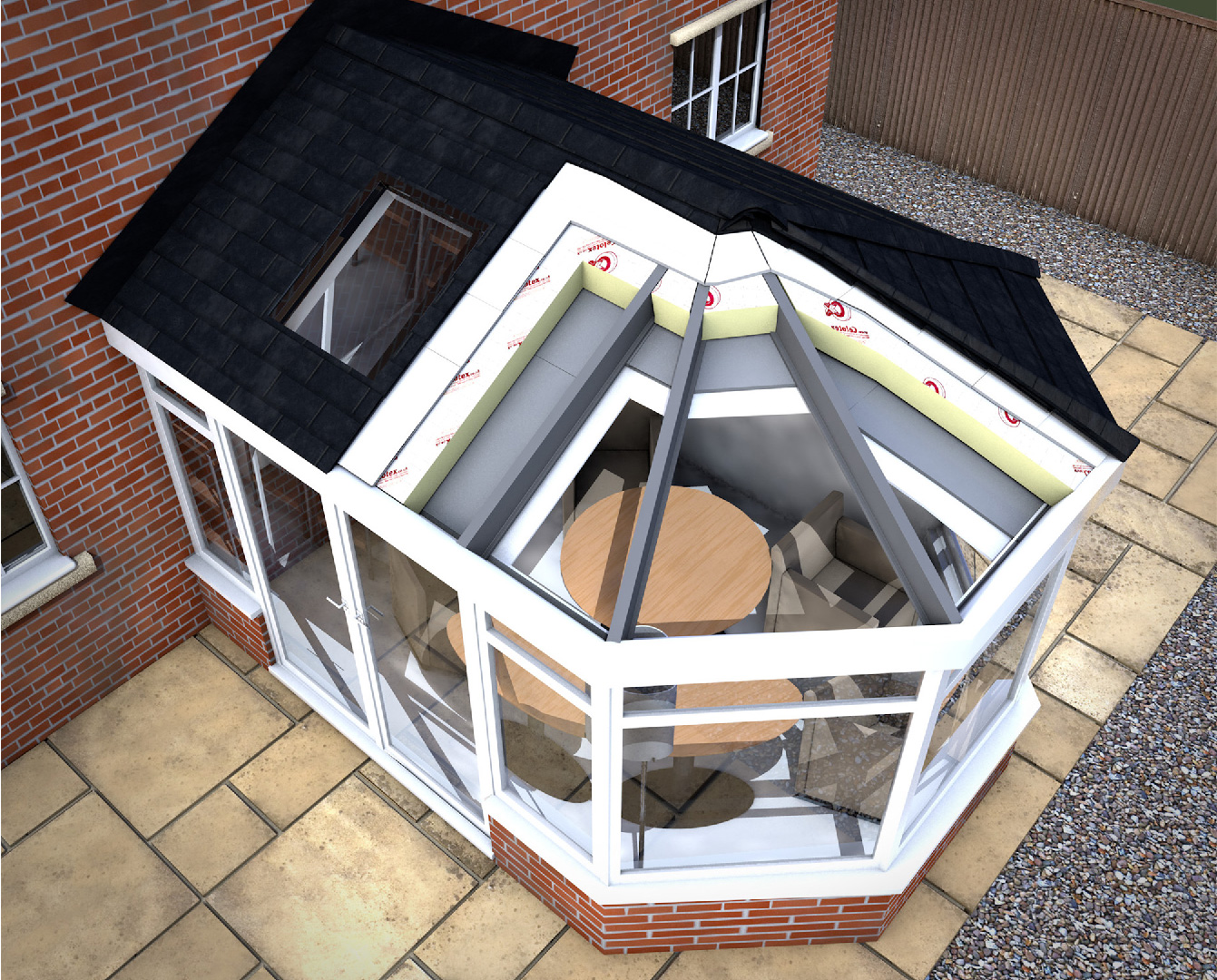

Below you will find a detailed system breakdown to help you know how the only conservatory warm roof system of its kind in the world can transform your existing conservatory or enhance your proposed new conservatory project.

The conservatory roof market is diverse and there are various options available to you. However, the Leka system is direct in its approach, providing only the best in materials following extensive tests. Every element of a Leka roof is engineered to perfection to create a roof that lasts. That is why it has a 40-year warranty. Please read the information provided below and contact us for more details if you do have any further questions.

The Leka System Warm Roof – Conservatory roof insulation

Conservatory roof insulation can only be one thing. The Leka System has been engineered through innovative methods, highly technical design protocols and practical experience to create probably the best conservatory roof system in the World currently.

Old and new conservatories can benefit from conservatory roof insulation improvements and so the Leka system answers the needs that provide better conservatory roof insulation with the visual aspect to match.

Find Out More

Roof Shape and Design

Although the Leka Conservatory Roof System has a number of important and highly engineered layers, the finish outside and inside is still very important.

The Leka System has been engineered in such a way that any existing conservatory design or shape can be replaced/installed with the Leka System Lightweight Tiled Roof.

The Leka Roof solves the challenge with a lightweight GRP construction and engineered tiles, which weigh around 12kg per square metre in Tapco slate, and 9.9kg per square metre in Metrotile concrete. There’s no aluminium or timber in the Leka roof. The ring beam, rafters and ridge are all made from glass reinforced plastic.

Using glass reinforced plastic allows for a structurally tested and far lighter alternative to aluminium and timber to create a truly lightweight conservatory roof. The weight of the Leka roof depends on the size of the construction but the average is just 30-40kg more than the equivalent glazed roof. In most cases, the existing structure of a conservatory can bear the weight. This is determined prior to construction.

Find Out MoreBritmet Shingles

The Britmet Shingle tile is designed to give an authentic shingle effect available in the largest standard colour range in the UK.

With all the characteristics you could expect from traditional American shingle, the Britmet Shingle is unique with a full dry-fix, interlocking hidden-fix design to keep your roof flush from fixings. Unlike traditional shingle, our lightweight design offers the perfect solution to any project. Despite having a steel base, the Britmet shingle weighs just under 7kg per sqm!

Most importantly, you can have a sound piece of mind using the Britmet Shingle as we are proud owners of an AA fire classification (BS476-3) (equal to traditional roof tiles and slates) and we are proud to offer a 40-year guarantee against weather penetration.

Find Out More

Britmet Liteslate

Introduced to the market in May 2019, Britmet's Liteslate is our innovative synthetic slate roofing tile made from 90% recycled polymers with all the characteristics you can expect from a traditional slate tile. Liteslate offers an authentic finish with riven edges, traditional colour choices and impeccable durability.

During the design process, real welsh slate was used in order to perfect the aesthetics and performance qualities of the LiteSlate. However, unlike natural slate, as a synthetic slate roofing tile, Liteslate won't crack, break, chip or delaminate due to its ground-breaking design and cutting-edge manufacturing process. Furthermore, the LiteSlate is designed with the environment in mind. Over 90% of the Polymers that LiteSlate is made from are recycled. In 2021, Britmet will recycle over three million kilograms of polypropylene during the manufacturing process.

In summer 2019, the LiteSlate passed its fire testing with a BS476-3 Fire Rating and new mould designs started development due to increasing customer demand for the composite slate. We have 7 production lines manufacturing the Liteslate ensuring that 14 slates are made every 45 seconds to supply our customer demand.

Find Out More